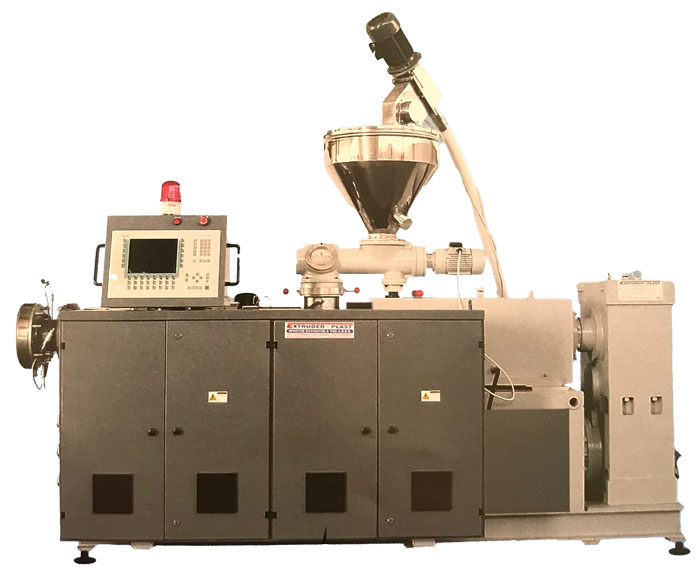

PLC controlled production line. Touch screen operation. Self Diagnostics. Remote troubleshooting capability by our technical service. Operating data storage capability for 30 profiles.

Data storage from production information for statistical evaluation. Timer for independent machine heat-up to decrease start-up times. The extruder is designed to allow easy access to control points. The motor is AC controlled with an Inverter.

The extruder barrel and screw are Nitrided Steel. The barrel is air cooled. The feed throat is water cooled to allow for easy material pick up by the screw. Screw’s thermoregulation is by oil. The tools are made to allow for higher production rates and superior quality.

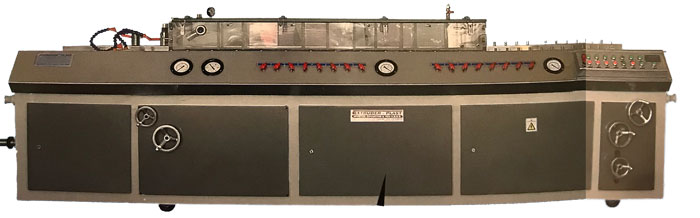

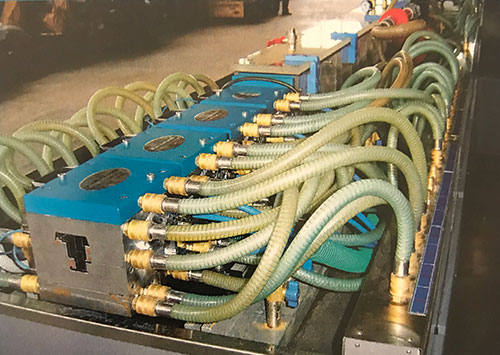

The calibration maintains the profile specifications within the required dimensions. Vacuum unit run on rails. Two until four vacuum pumps working in these machines. All the water tanks are stainless steel.

The tracks have 1.8 until 3 meters length, with designed footers to maintain contact with profiles. Individual puller tracks and double air pistons.

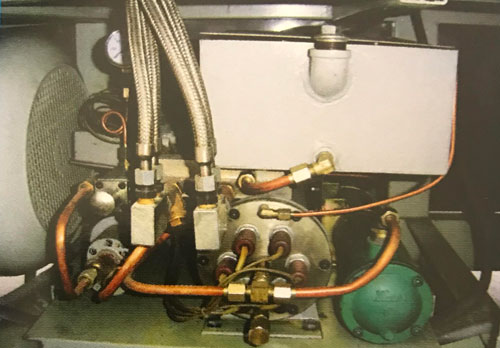

Screws thermoragulation system

Extruder's Vacuum System

Extruder's electrical panel

Vacuum Extruder System

CONICAL EXTRUDERS

| ΕΧ 45/90 | ΕΧ 55/110 | ΕΧ 55/115 | ΕΧ 65/132 | ΕΧ 80/156 | ΕΧ 92/188 | |

|---|---|---|---|---|---|---|

| Screw diameter | 45/90 | 55/110 | 55/115 | 65/132 | 80/156 | 92/188 |

| Efection working length mm | 989 | 1200 | 1200 | 1440 | 1800 | 2500 |

| Rotating direction | Turning outwards with counter rotating | Turning outwards with counter rotating | Turning outwards with counter rotating | Turning outwards with counter rotating | Turning outwards with counter rotating | Turning outwards with counter rotating |

| Max.screw revolution kN | 1-45.5 | 1-30.2 | 1-30.2 | 1-34.7 | 1-38.2 | 1-33.1 |

| Main motor power rpm | 15 | 22 | 22 | 37 | 55 | 90 |

| Cylinder resistance number | 3x4kw | 4x5kw | 4x5kw | 4x6kw | 5x7kw | 7x10kw |

| Cylinder resistance power kw | 12 | 20 | 20 | 24 | 35 | 70 |

| Cylinder cooling system | Air | Air | Air | Air | Air | Air |

| Screws cooling system | Oil | Oil | Oil | Oil | Oil | Oil |

| Installed electric power kw | 25 | 34 | 34 | 52 | 74 | 125 |

| Net weight kg | 3000 | 3500 | 3500 | 4000 | 5000 | 10000 |

| Dimensions L/W/H-m | 3.4/1.3/2.2 | 3.6/1.3/2.2 | 3.6/1.3/2.2 | 4.3/1.5/2.5 | 4.8/1.6/2.5 | 6.7/1.6/2.8 |

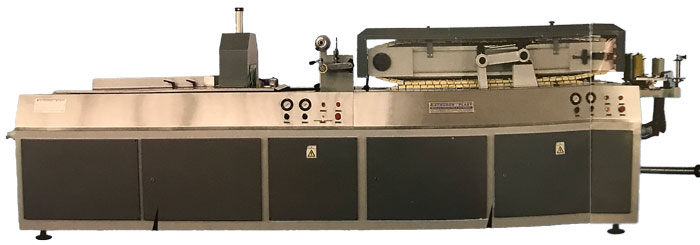

VACUUM MACHINE

| MB 4000 | MB 6000 | MB 8000 | |

|---|---|---|---|

| Power of water pump kw | 1.5 | 1 x 4 / 1 x 1.5 | 1 x 5.5 / 1 x 1.5 |

| Power of vacuum kw | 2 x 5.5 | 4 x 5.5 | 4 x 5.5 |

| Installed electric power kw | 15 | 30 | 32 |

| Fan for cooling air kw | 0.75 | 0.75 | 0.75 |

| Operating pressure mmHg | 350 | 350 | 350 |

| Power of motion engine kw | 1.1 | 1.1 | 1.1 |

| Motion distance mm | 1200 | 1200 | 1200 |

| Net weight kg | 1200 | 1500 | 1800 |

| Dimensions L/W/H-m | 4.1/1.2/1.2 | 6.1/1.2/1.2 | 8.1/1.2/1.2 |

ΜΤΕ 18.24

ΜΤΕ 26.24

HAUL-OFF CUTTING UNIT

| MTE 18.24 | MTE 26.24 | |

|---|---|---|

| Main motor power kw | 0.75x2 | 1.5x2 |

| Chain-belts width mm | 240 | 240 |

| Chain-belts length mm | 1800 | 2600 |

| Speed adjust m/min | 0-10 | 0-6 |

| Main motor power (cutting) m/min | 2.2 | 2.2 |

| Main motor power (suction) kw | 0.75x2 | 0.75 |

| Disc diameter mm | 350 | 350 |

| Net weight kg | 1200 | 1500 |

| Dimensions L/W/H-m | 5.5/1.1/1.6 | 6.3/1.1/1.6 |