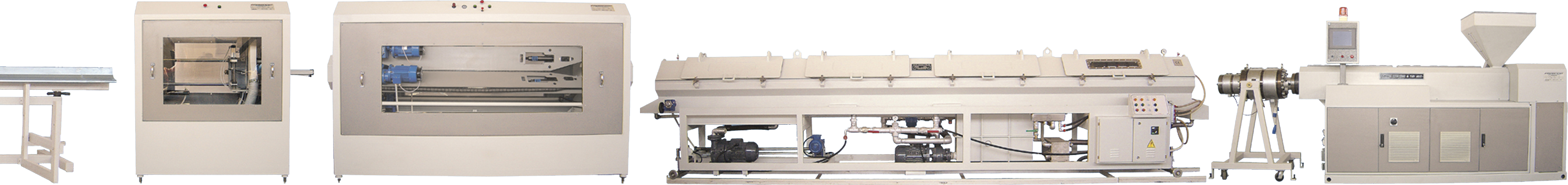

PLC controlled production line. Touch screen operation. Self-Diagnostics. Remote troubleshooting capability by our technical service. Operating data storage capability for 30 profiles. Data storage from production information for statistical evaluation. Timer for independent machine heat-up to decrease start-up times. The extruder is designed to allow easy access to control points. The motor is AC controlled with an Inverter.

The extruder barrel and screw are Nitrided Steel form THYSSEN. The barrel is air cooled. The feed throat is water cooled to allow for easy material pick up by the screw. The extruder screw is a Bar-screw type with multiple mixing zones. The dies are spiraled to allow for higher production rates and superior quality. The calibration maintains the pipe specifications within the required dimensions.

There are two cooling baths the first of which is also under vacuum for dimensional stability of the pipe. Specially designed spray nozzles remove effectively the heat from the pipe to maintain dimensions. The pullers have three or four tracks with designed footers to maintain contact with pipes in dimensions from 20 – 300mm. The upper tracks are pushed with air pistons for contact whereas the lower tracks are electrically adjusted for the desired pipe diameter.

EX 80 pe

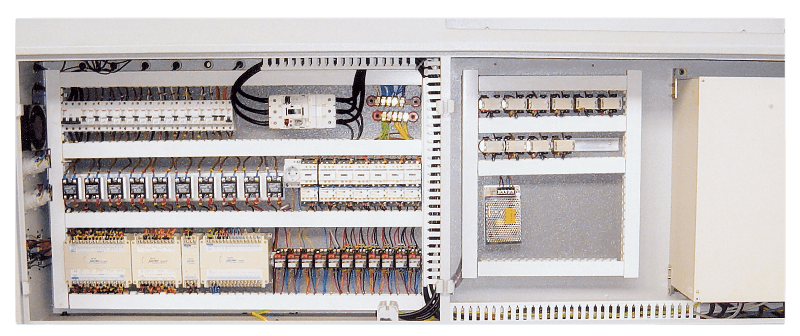

Extruder's electrical panel

Extruders

| ΕΧ 35pe | ΕΧ 60pe | ΕΧ 75pe | ΕΧ 90pe | |

|---|---|---|---|---|

| Screw diameter Φ | 35 | 60 | 75 | 90 |

| L:D | 28 | 33 | 33 | 33 |

| Max. back pressure kn | 430 | 1150 | 1300 | 1500 |

| Screw / min rpm | 150 | 160 | 160 | 160 |

| Main motor power kw | 6 | 55 | 75 | 150 |

| Reducer rate | 1\12 | 1\12 | 1\12 | 1\12 |

| Barrel Heating Zones | 3x2kw | 5x3kw | 6x3kw | 7x3kw |

| Total Heating Zones Power kw | 6 | 15 | 18 | 21 |

| Barrel cooling | Air | Air | Air | Air |

| Installed electric power kw | 14 | 73 | 95 | 175 |

| Net weight kg | 600 | 1300 | 1800 | 2500 |

| Dimensions L/W/H-m | 1.5/0.6/1.2 | 2.7/0.95/1.8 | 3.2/1.05/1.85 | 3.8/1.15/1.95 |

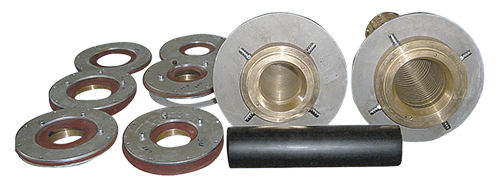

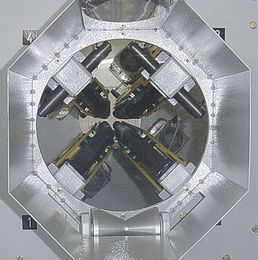

Pipes's Head

Pipes's Head pe - 110 300Φ

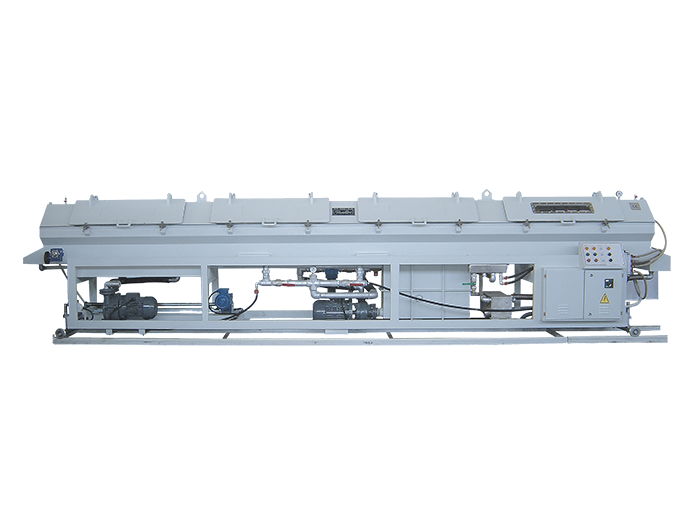

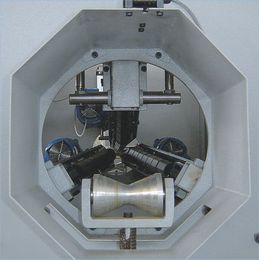

Calibration System

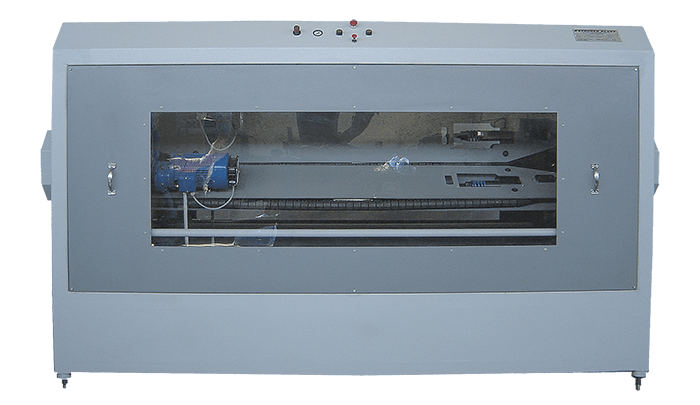

Vacuum Machine

| MBV 315/6000 | MBV 250/6000 | MBV 125/6000 | |

|---|---|---|---|

| Measures of extrusion material Φ mm | 110 – 315 | 50 – 250 | 20 – 125 |

| Power of circulation pump kw | 7,5 | 5,5 | 5,5 |

| Power of vacuum pump kw | 3 | 2,2 | 2,2 |

| Power of motion engine kw | 1 | 0,75 | 0,75 |

| Installed electric power kw | 1 | 0,75 | 0,75 |

| Suction capacity of vacuum pump m3/h | 12 | 9 | 9 |

| Heat of circulation water oC | 15 | 15 | 15 |

| Average water pressure m3/h | 25 | 25 | 25 |

| Fountain numpers pieces | 160 | 140 | 120 |

| Dimensions L/ W /H m | 6,5/1/1,5 | 6,5/1/1,5 | 6,5/0,7/1,3 |

| Net weight kg | 1500 | 1200 | 1000 |

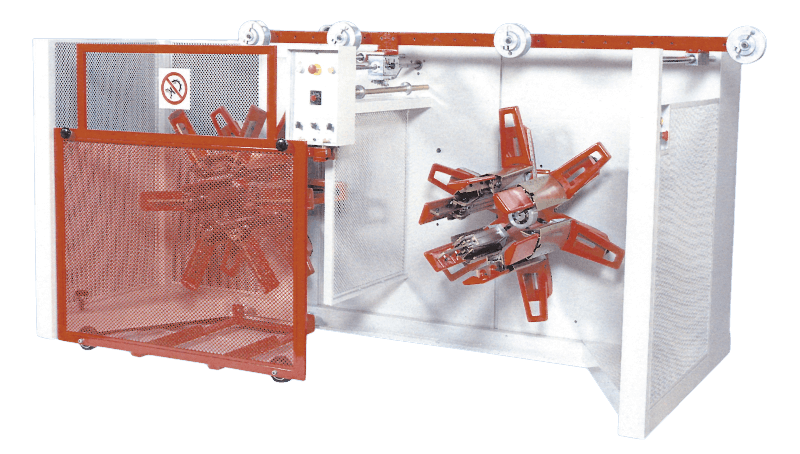

ΜΤΕ 3

ΜΤΕ 4

ΜΤΕ 3

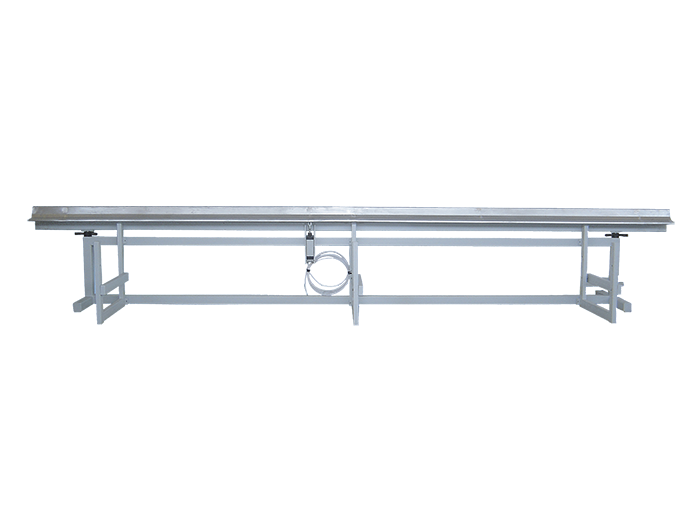

Haul-off Cutting Unit

| MTE 3 | MTE 4 | |

|---|---|---|

| Main motor power kw | 1.5x3 | 1.5x4 |

| Num. of Chain-belts | 3 | 4 |

| Chain-belts length | 2500m | 2500m |

| Speed adjust m/min | 0-8,5 | 0-8,5 |

| Power of motion engine kw | 0,55 | 0,55 |

| Pipe's diameter mm | 20-200 | 25-250 |

| Net weight kg | 1200 | 1500 |

| Dimensions L/W/H-m | 3,2/1,3/1.9 | 3,2/1,3/1.9 |

Cutting Unit

| VCT-200 | RCT-160 | RCT-250 | |

|---|---|---|---|

| Main motor power (cutting) kw | 4 | 2,2 | 2,2 |

| Disc diameter mm | 530 | ||

| Cutting pipe diameter mm | 20-200 | 50-160 | 50-250 |

| Maximun wall thickness mm | 15 | 15 | 20 |

| Speed of cutting unit m/min | 8 | 10 | 10 |

| Motor revulation rpm | 1400 | 1400 | 1400 |

| Rotation speed of saw rpm | 344 | 277 | |

| Required pressure air bar | 6 | 6 | 6 |

| Working axis mm | 1000 | 1060 | 1060 |

| Dimensions L/W/H-m | 2/1,3/1.9 | 2,5/1/1.5 | 2,5/1,3/1.7 |

| Net weight kg | 800 | 1000 | 1500 |

VCT-200

Vertical Cutting Machine

RCT-160

Rotating Knife

VCT-200

Accumulator

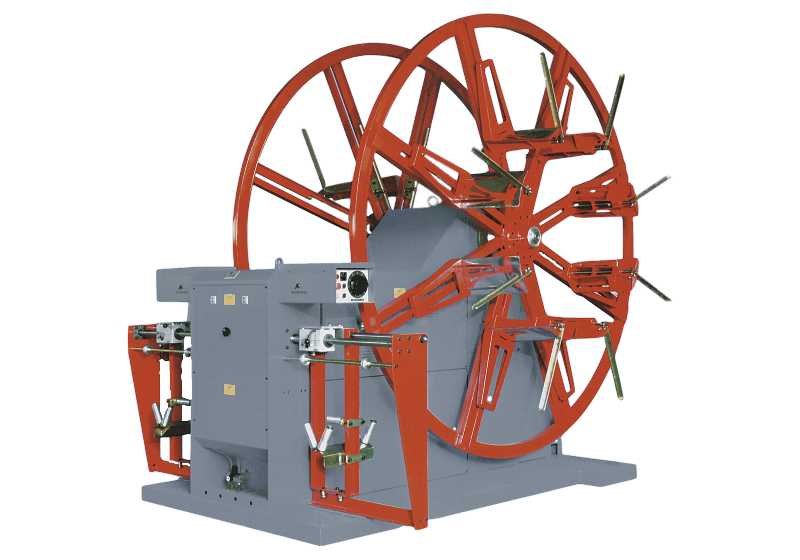

Winding Machines

| MT3 1500 | MT5 2700 | MT6 3200 | |

|---|---|---|---|

| Outside diameter Φ | 1500 | 2700 | 3200 |

| Inside diameter Φ | 330 – 1000 | 600 – 1900 | 800 – 2200 |

| Brackets adjust mm | 50 – 300 | 100 – 400 | 150 – 500 |

| Brackets | 6 | 8 | 8 |

| Pipe diameter Φ | 16 – 40 | 20 – 75 | 40 – 110 |

MT3 1200

MT3 1200